Rolls for Steelmaking

YODOKO rolls, produced with some of the world's largest centrifugal casting equipment and unparalleled technologies, boast an extensive track record in the steel industry.

What are rolls for steelmaking?

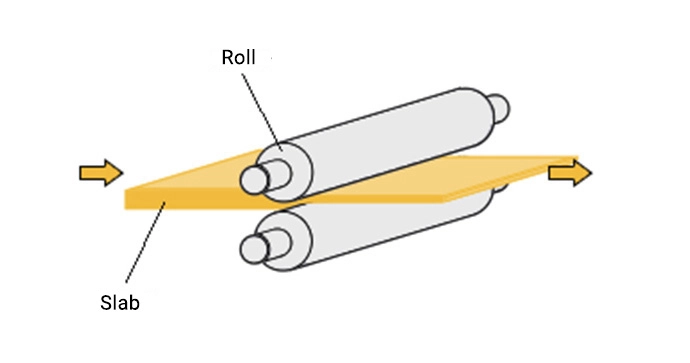

Steel sheet materials (slabs) are passed through rotating rolls to reduce their thickness and improve their mechanical properties. The thinned steel sheets then undergo various processes to create a wide range of products such as steel sheets for shipbuilding and automobiles, building materials, and other products that support our daily lives.

Rolls are an important product that support the foundations of people's lives.

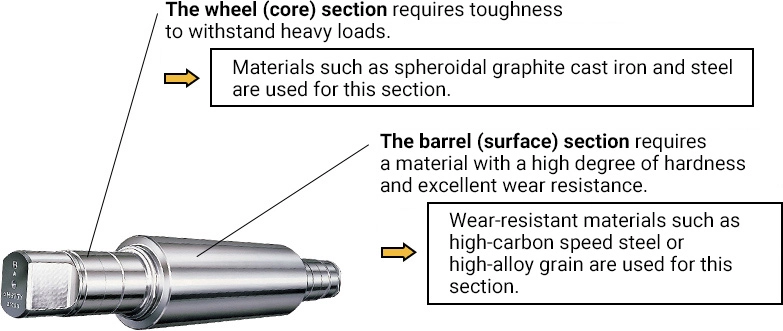

Rolls for rolling mills need to have barrel and shaft sections with different material properties.

YODOKO employs the centrifugal casting method and the YPM molten metal cladding method to manufacture composite rolls that meet the material property requirements of both the barrel and shaft sections.

Work rolls for thick plate rolling

In general, steel sheets with a thickness of 6 mm or greater are referred to as thick plates. Thick plates used in bridges, marine vessels, LNG tanks and other applications are created by heating and applying pressure to steel sheet materials (slabs) to making them thinner.

Work rolls for thick plate rolling, which handle large and thick materials, require the roll itself to be large. In addition, the materials requirements, including toughness, wear resistance and resistance to heat cracking, are also becoming stricter each year. YODOKO is one of the world's pioneers of centrifugal casting equipment, and has been manufacturing and selling work rolls for thick plate rolling since 1975. Rolls cast using some of the world's largest centrifugal casting facilities boast a top market share not only in Japan but worldwide.

Work rolls for thin sheet rolling

In general, steel sheets with a thickness of less than 6 mm are referred to as thin sheets. YODOKO manufactures work rolls for various rolling stands including roughing and finishing, and provides rolls made from the right materials to suit various usage conditions.

In recent years, advances in rolling technologies and the increase in high-quality steel sheets have led to tougher requirements for rolls in terms of wear resistance, roughening resistance and accident resistance. To satisfy these requirements, we have been manufacturing rolls that meet customer specifications using advancements such as wear-resistant high-alloy grain materials and centrifugally-cast high speed steel.