Rolls for Papermaking, Rubber and Vinyl

Integrated calender rolls

We have been manufacturing integrated calender rolls for over 40 years

By manufacturing the rolls with centrifugal casting equipment, we achieve high hardness and long life, and boast a delivery track record of over 6,000 rolls, including those for overseas customers.

Contact

Assembled rolls

We design and manufacture a wide range of rolls to suit different applications, including lightweight construction and surface heating.

We have a track record of adoption for calenders and press parts designed to reduce the weight of rolls.

Contact

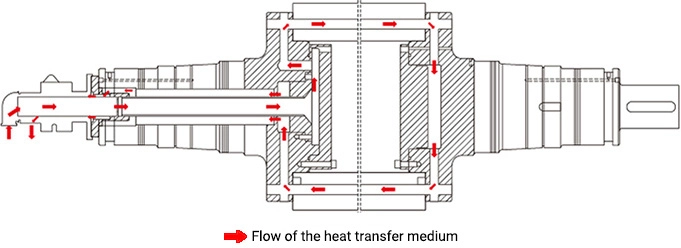

Heating rolls

This is a type of assembled roll with a structure that allows the surface of the roll to be heated by passing a heat transfer medium through the inside.

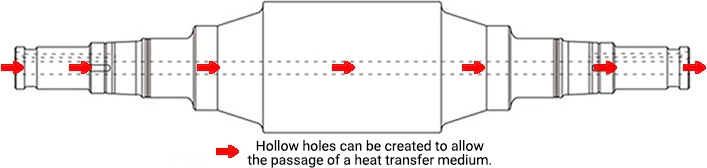

①Hollow assembly type

This type is often employed for machine calenders with a large internal volume where hot water is used as the primary heat source.

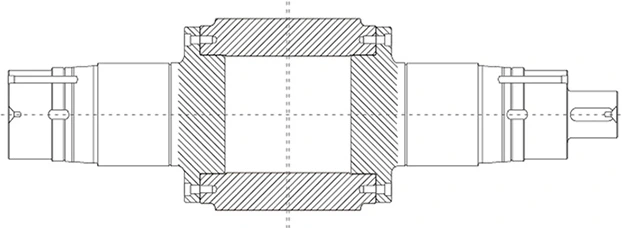

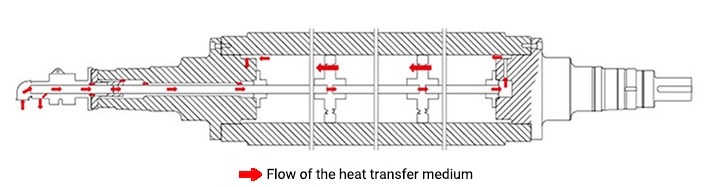

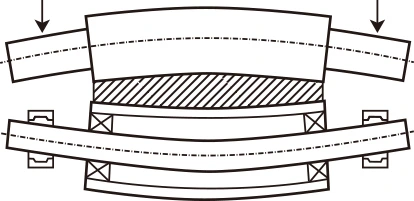

②Displacer (core) type

This type is often used for super calenders, and recently has also been adopted for machine calenders. Hot water is used as the primary heat source. As the flow speed of the heat source is prevented from slowing internally, the surface temperature features superior uniformity to the hollow assembly type.

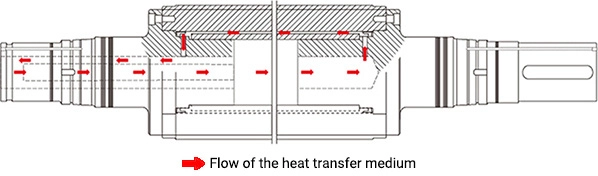

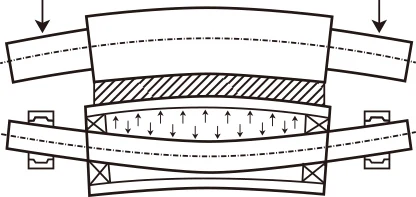

③Assembly-type drilled rolls

Several through-holes (drilled holes) are arranged in the barrel section of the roll, allowing liquids to flow even closer to the barrel surface than conventional heating rolls. This offers superior surface temperature uniformity to the displacer type.

Contact

Swimming rolls

YODOKO began manufacturing swimming rolls after forming an alliance with the German company ANDRITZ Küsters in 1967. In the years since, we have designed and manufactured more than 3,000 swimming rolls, including for overseas customers. These are used in every part of paper machines, including calenders, super calenders, press parts, size presses and breaker stacks.

The rolls are controlled using hydraulic systems. Hydraulic pressure is used to induce deflection in the rolls, enabling the uniform correction of distorted nip profiles.

Contact

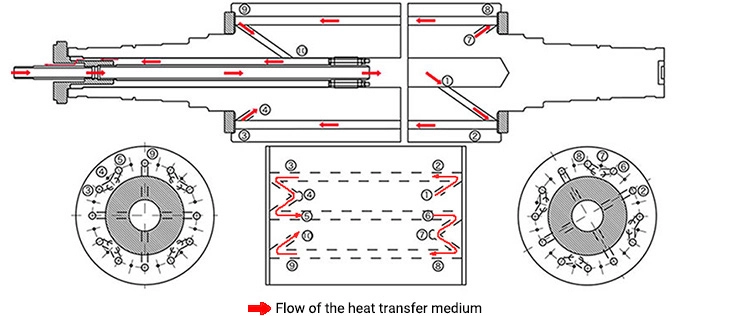

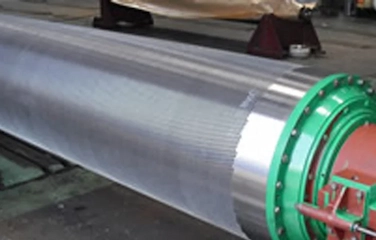

Drilled rolls

These are rolls designed to control the temperature at the roll surface by passing oil, hot water or steam through the inside of the roll. This design makes it easy to control the temperature and features minimal temperature variation. Uniform gloss and smoothness can be obtained with low load. These types of rolls are also used in the rubber, plastic, food and textile industries.

Contact

YODOGAWA-FUYO Co., Ltd.

Corporate Profile

YODOGAWA-FUYO, a subsidiary of YODOKO, Ltd., has been developing and manufacturing paper-making machinery for many years. Particularly in the field of paper sheet forming machinery, YODOGAWA-FUYO has fully leveraged design capabilities based on creative ideas and extensive technological capabilities to deliver its products to domestic paper companies, various other companies, as well as customers in Asia. In addition, using its advanced technological capabilities in paper-making machinery, YODOGAWA-FUYO is also involved with the development and manufacturing of general industrial machinery spanning numerous fields. Utilizing its manufacturing experience in Fuji, Shizuoka Prefecture, where the papermaking industry is concentrated, YODOGAWA-FUYO also provides flexible services to repair and modify older facilities.

Main design and production items (related to paper sheet forming machinery)

- Suction rolls

- Felt rolls

- Press equipment modification

- Design and production of dry parts

- Design and production of dryer rolls

- Canvas rolls

- Dry part modification

- Paper rolls

- Various other rolls

- Carrier pulleys

- Design and production of reel equipment

- Modification or reel equipment

- Design and production of winder and unwinder equipment

- Modification of winder and unwinder equipment

- Partial modification of off-coater machines

- Design and production of cutter equipment

- Design and production of embossing calender equipment

- Design and production of rewinding equipment

- *We welcome requests for consultation about other paper-making machinery, industrial machinery, and equipment.

Contact

| Company name | YODOGAWA-FUYO Co., Ltd. |

|---|---|

| Address | 4-9-25 Yokowari, Fuji-shi, Shizuoka Prefecture, 416-0944, Japan |

| TEL | +81-545-61-1517 |

| FAX | +81-545-64-5060 |

| info@yodogawa-fuyo.co.jp | |

| URL | http://www.yodogawa-fuyo.co.jp/ |